The dynamics of the manufacturing industry have changed significantly over the past few decades. Environmental sustainability has now become a key consideration as the world worries about depletion of resources. Rather than the simple focus on engineering and production aspects, manufacturers are now compelled to evaluate customer outcomes too. And then there is the impact that manufacturing has on people, cities and communities as a whole.

As manufacturing comes face to face with the digital age, the workforce has fared no better, with about 70 million people losing jobs thanks to automation. The silver lining is that 133 million new jobs are also estimated to be created in the next two years. However these jobs require a different set of skills. Training needs to be directed towards new innovations, to upskill the present workforce and to equip them with a more advanced skillset than ever before.

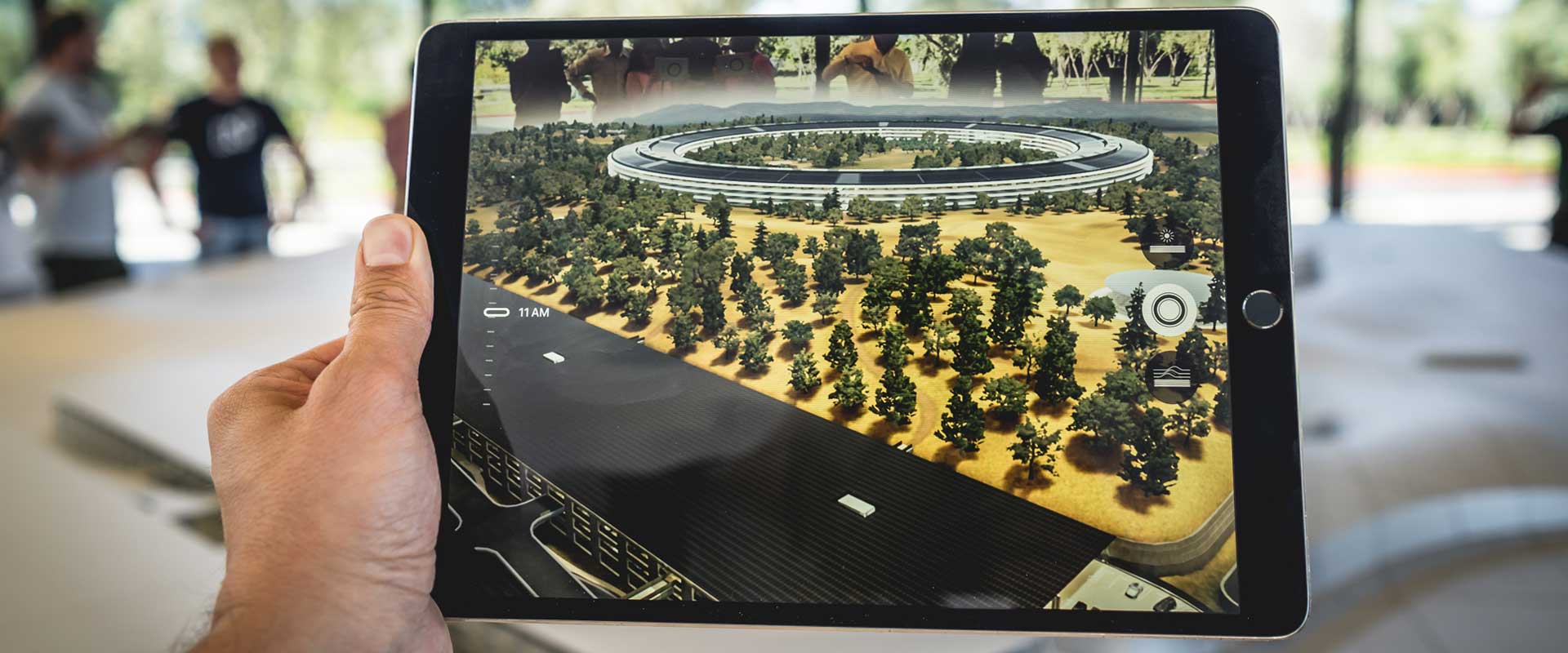

As skillset enhancement requirements seek to redefine training methods, Augmented Reality (AR) and Mixed Reality models come in handy, to complement the advancements required in the skillset of the workforce. These models enhance safety standards and improve output simultaneously. As intelligent apps guide the workforce by collaborating to unify data, processes, devices and relationships, skill gaps are easily overcome. This promotes lower levels of accidents, and a reduction in product or brand damage.

Achieving digital excellence in manufacturing is all about proactive engagement – throughout the product life cycle and after the point of sale too. Technologies such as Digital Twins, IoT and 3D modelling can be used to modernize the factory floor and empower the workforce. Technicians can use these solutions to deliver predictive services, increase failure prevention and reduce maintenance costs. Once the product is ready to launch, the customer experience becomes the focal point. The sales and service teams must also be empowered with smart processes and industrial IoT, to gauge profit margins and customer expectations, and then customize and personalize client relationships to improve sales.

The relationship of today’s manufacturer does not stop at the point of sale. Intelligent products ensure connectivity back to the cloud, which means an enhanced customer experience. Through AI-driven initiatives, the manufacturer remains connected with the customer throughout the life cycle of the product, obtaining new insights and using predictive analytics to provide the client services such as remote monitoring and maintenance of the product.

Mixed reality is a fusion of the augmented with the real. Powerful insights are made possible with VR, while MR allows for visualization of products as manufacturers design, build and sell these products and also provide enhanced customer service.

At Digitalgogia, we have created a new niche in the world of manufacturing. Let us See Beyond what is visible and reimagine smart manufacturing together.